Home

Forensic Welding Experts

For over 35 years WJMG’s dedicated team of industry-leading professionals has specialized in Forensic Metal Investigations, Welding, Code Compliance, Metallurgy, and Nondestructive Testing.

WJMG practices the collective expertise for every project, with precise and reliable solutions tailored to client needs. With a strong foundation in education, certifications, and hands-on experience, WJMG’s team is committed to advancing industry standards and providing innovative solutions to today’s complex challenges.

Welder

Certification

Welder Certification

Code Compliance

AWS ASME API

The code and procedure will be determined by what type of job the welder is being certified for. There are structural welding tests, pipe welding tests, aerospace welding tests, food service welding tests and more.

The welder must have a copy of the WPS that they will be certified on, the (PQR) and be dressed in PPE for welding. WJMG can provide the welding machines and coupons or the welder can bring their own.

Mechanical

Testing

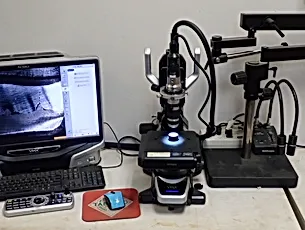

Mechanical Testing

- Laboratory Analysis

- Field Inspection

- Metals Testing

- Guided Bend Test – face, root, side

- Macro-etch Fillet Weld

- Nick Break, Charpy Impact, Tensile Test

- Coefficient of Friction / Slippage Test

- Post Weld Heat Treat, Small Furnace, Residual Stress Relief, Induction Heating

- METALAX – Vibratory Stress Relief (VSR)

- Microhardness Traverse – Vickers, Knoop

- Macrohardness – Brinell Traverse; Rockwell B, C

- Feritscope – Ferrite Content Measurement

Instrument

Validations

Instrument Validations

- Dial Caliper, Micrometer

- Electrical Instrument (ammeter, voltmeter, WFS)

- Epsilon Strain Gauge

- Filler Weld Gauges (set 5 or 7)

- Hardness Test Instrument

- Harmonic Tests (welding power supply)

- Micrometers

- Pressure Gauges

- Skidmore – Wilhelm

- Thread Profile, Depth Gauge, Bore Depth

- Torque Wrenches

- Tape Measure, Rulers, Scales

WJMG

Institute

WJMG Institute

- NDT Classroom Certification for

- Level I or II in –

- CVWI, VT, PT, MT, UT, PAUT.

- Certification course for welder certification thought AWS

- AWS D1.1, ASME IX, B31.3

- ASNT SNT-TC-1A Level II UT

- Certification course ANST SNT-TC-1A Level II VT, MT, PT

- SENSE program 30 days, 12 days hands on for $5,000

Stress Relief, Metalax,

Heat Treatment

Stress Relief, Metalax, Heat Treatment

- Lindberg Heater Treater (3’x3’x3′)

- Skutt Oven (2’x2’x6′)

- Shop Oven (2’x2’x2′)

- Big Heater treater – tank vessels (5’x5’x16′)

- Portable Induction Coils for Welds

- Vibratory Weld Conditioning – Meta-Lax

- Vibratory Stress Relief – Meta-Lax